Liquid Cooled EV Charging Station Cables: The Key to Efficient and Rapid Charging

In the continuous development process of the electric vehicle (EV) industry, the advancement of charging technology is of great significance for achieving a fast, efficient, and safe charging experience. Liquid-cooled EV charging cables and connectors are an important breakthrough, especially suitable for high-power application scenarios where traditional air-cooling methods cannot handle the high heat generated.

Liquid-cooled charging technology works by circulating a liquid coolant, such as Dimethyl silicone oil and ethylene glycol, through specially designed channels/tubes within the charging cable and connector. As high-power charging generates heat due to electrical resistance, the coolant absorbs this heat and carries it to a heat exchanger where it is safely dissipated. The cooled liquid is then recirculated to maintain optimal temperatures, ensuring efficient and safe charging. Integrated temperature sensors monitor the system in real-time, preventing overheating and enabling thinner, more flexible cables. This innovative approach allows for ultra-fast charging up to 500 kW or more, while enhancing safety, durability, and user convenience for electric vehicles.

The main advantage of liquid-cooled electric vehicle charging cable is their ability to maintain a stable temperature. The coolant circulates inside the cable, taking away the heat generated by the conductors during high-power charging, enabling the connectors and cables to carry larger currents and meet the needs of modern fast charging.

(2) Types of Coolant

-

Dimethyl Silicone oil Solution: Dimethyl silicone oil excels in high-power charging applications due to its exceptional thermal stability, maintaining performance across extreme temperatures (-50°C to +200°C) and resisting degradation under intense heat. Its non-conductive properties ensure electrical safety, while chemical inertness prevents corrosion and extends component lifespan. With low volatility, it minimizes evaporation losses, reducing maintenance needs. Environmentally friendly and non-toxic, it aligns with sustainable practices.

-

Ethylene glycoll Options: Ethylene glycol offers superior heat transfer efficiency, critical for dissipating heat during fast charging. Cost-effective and widely compatible with existing automotive cooling systems, it provides freeze protection in sub-zero climates when blended with water. Formulated with corrosion inhibitors, it safeguards metal parts, making it a practical choice for large-scale, budget-conscious implementations

3. Classification of Liquid-Cooled EV Connectors

-

GB/T Standard: Widely used in China, focusing on DC charging and electronic lock mechanisms. We Fiver offers 1000V DC 600A Liquid Cooled GBT Charging Cables for Chinese domestic market.

-

CCS2 Standard: Widely adopted in Europe, integrating AC and DC charging interfaces to meet the diverse charging needs of European users. Fiver have introduced our 1000V 500A 600A and 700A Liquid Cooled CCS2 Charging Cables for European market.

-

NACS (Tesla) Standard: Tesla's proprietary standard, integrating AC and DC functions into a single connector design to optimize the charging of Tesla vehicles. Fiver have launched our 1000V 600A Liquid Cooled NACS Charging Cable, for North America market.

-

Megawatt Charging Standard: is a groundbreaking technological framework designed to enable ultra-fast charging for heavy-duty electric vehicles (HDVs) such as trucks, buses, and industrial machinery, as well as emerging applications like electric ships and aircraft. It represents a quantum leap beyond conventional charging standards, addressing the critical need for rapid energy replenishment in high-power use cases. Fiver introduced their liquid cooled 1500V 1500A Megawatt charging cables & 2.25MW Megawatt Charging Inlets. for heavy duty electric trucks.

4. Liquid-Cooled Cable Structure Types

-

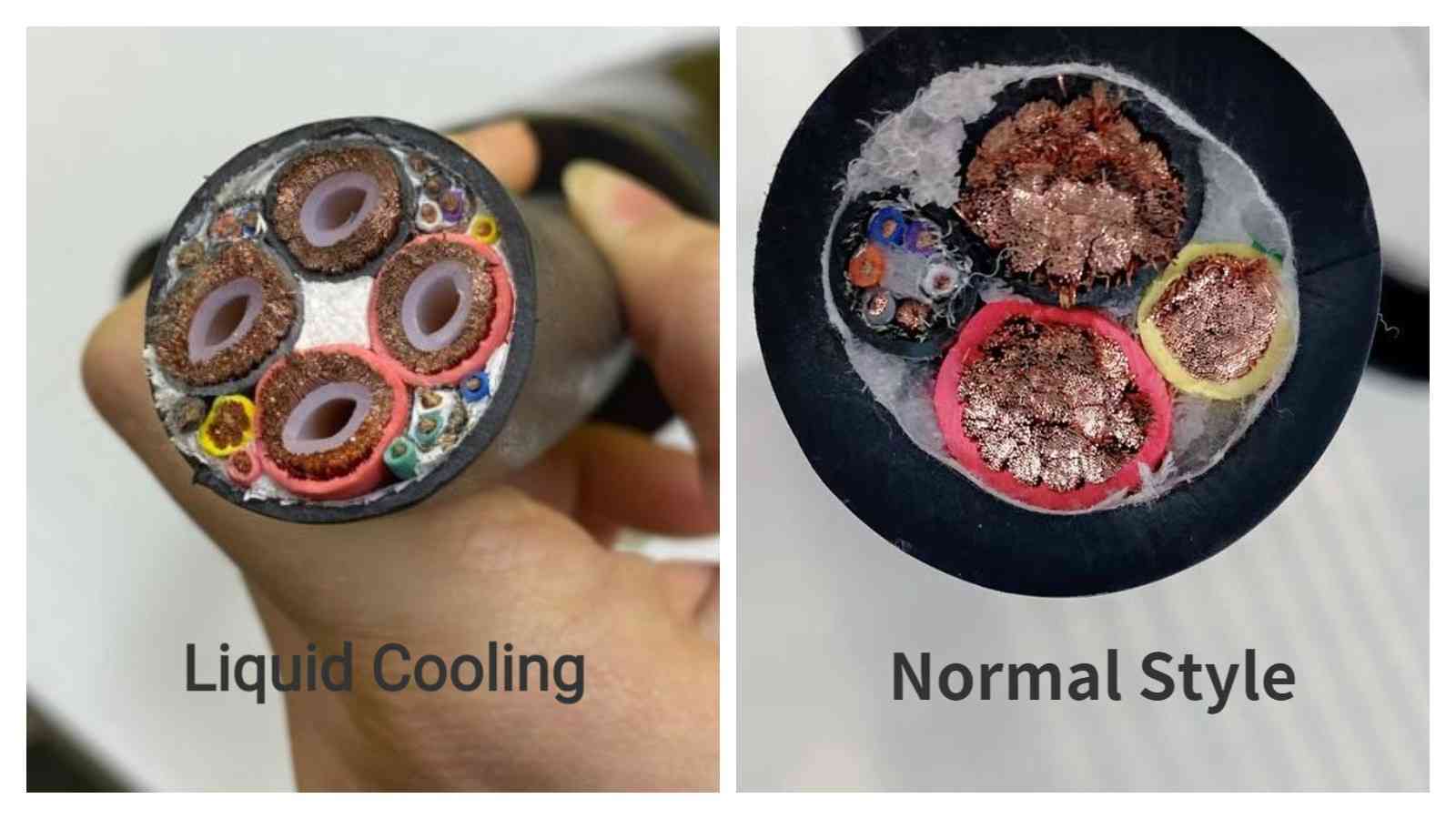

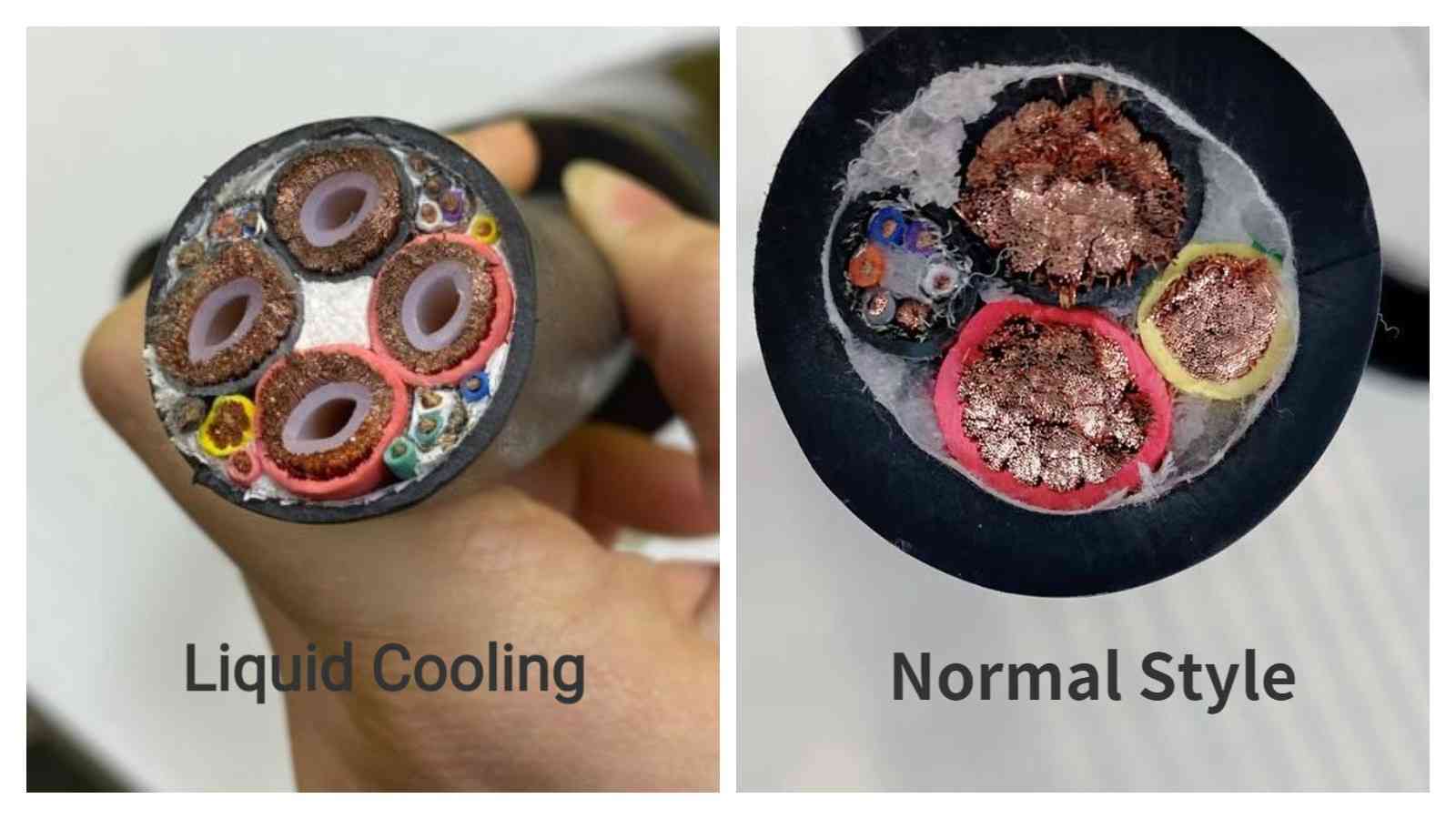

Immersion Structure: The coolant directly contacts the copper conductor, with high cooling efficiency, but the low-pressure requirements and large pipe diameter limit the flexibility.

-

Non-immersion Structure (Adopted by Fiver): The cooling pipe is surrounded by copper wires, balancing flexibility and safety, reducing the risk of coolant leakage and improving insulation performance, suitable for high-frequency usage scenarios.

-

-

5. Innovations and Advantages of Fiver

-

Optimized Cooling Tube Design: Adopting 4.5/6mm cooling tubes, reducing the cable diameter and weight, and improving flexibility and operability.

-

Excellent Durability and Flexibility: Tested to withstand extreme physical pressures such as vehicle rolling without affecting performance.

-

Advanced Coolant Selection: Using dimethyl silicone oil coolants, meeting environmental standards, extending the cable life, and ensuring stable performance.

-

High-Standard Safety Assurance: Through the non-immersion structure and careful material selection, reducing the risks of coolant leakage and conductivity problems.

6. Key Components of Liquid-Cooled Electric Vehicle Charging Station Cables

-

Liquid Cooling Pipes: Using high-performance materials such as PTFE and FEP, with high temperature resistance and strong insulation properties, ensuring stable cooling under different environmental conditions.

-

Charging Connectors: Adopting quick-twist, quick-plug, and pagoda connectors to promote the efficient flow of coolant and having a self-sealing function to prevent leakage.

-

Sealing System: The high-performance sealing system ensures that the plugs, sockets, and internal pipes are airtight under high pressure and has passed strict tests to meet the IP67 standard, resisting environmental and wear factors.

7. Rigorous Testing to Ensure Reliability and Safety

-

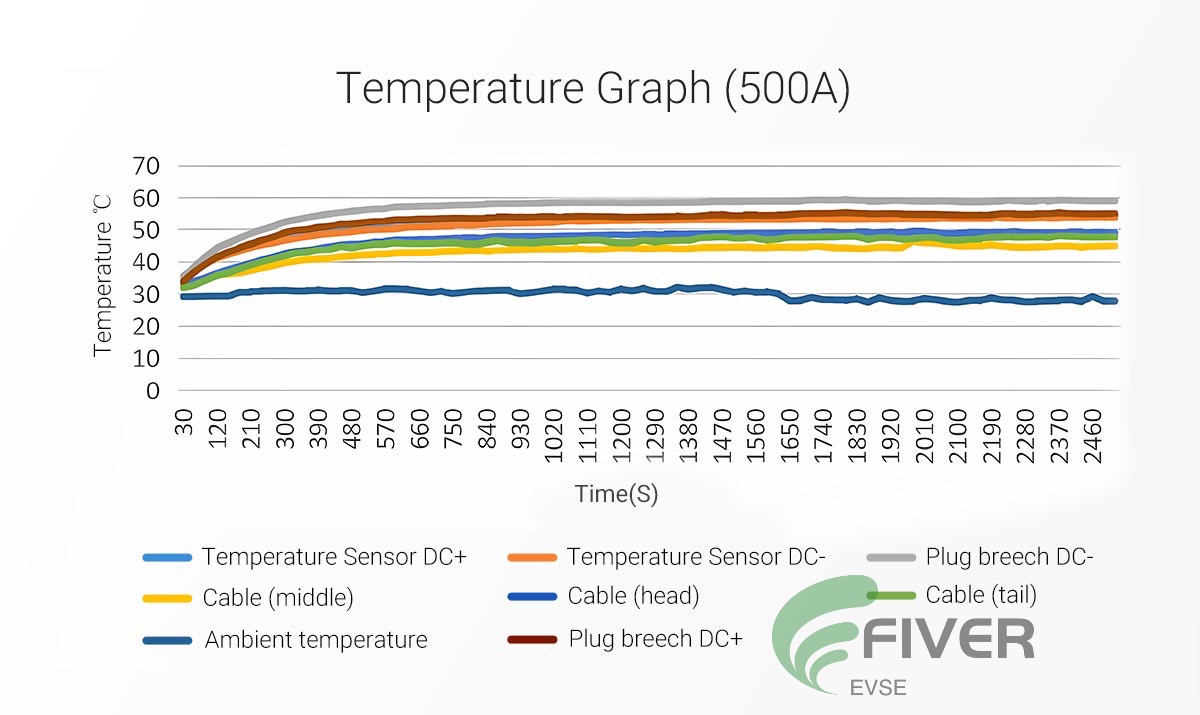

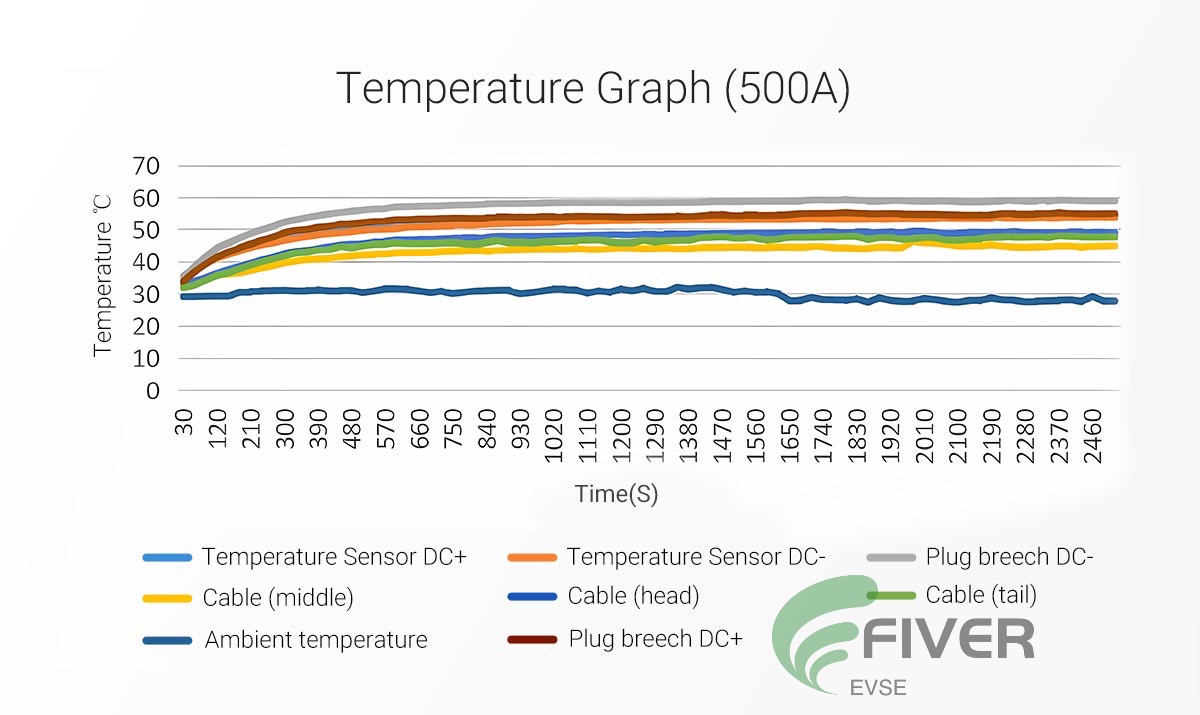

Temperature Rise Test: To evaluate the heat dissipation effect of the cable during charging. Fiver's ev charging station cable have a temperature rise below 50K during high-current charging.

-

Sealing Performance Test: Conducting multiple sealing tests, including airtightness and high-temperature operation tests, to ensure that the coolant does not leak.

-

Short-Term Failure Simulation Test: Simulating the sudden stop of coolant flow to test the safety performance of the cable components and prevent overheating.

-

Mechanical Durability Test: Through bending and compression tests to simulate actual physical stress scenarios and evaluate the cable's resistance to damage.

8. Advantages of Liquid-Cooled Charging Technology

-

Higher Charging Power: Supporting a charging current of up to 700A for CCS Charging, 600A for NACS Charging; 600A for GBT Charging. enabling fast charging without overheating.

-

Cost-Effective Design: Efficient heat dissipation allows for the use of smaller conductors, reducing material costs, and the lightweight cable is convenient for operation and installation.

-

Enhanced User Experience: The compact design and lightweight materials improve the convenience of plugging and unplugging.

-

Long-Term Durability: The choice of biodegradable coolant and durable materials extends the service life of the cable and reduces the replacement cost for operators.

Fiver is committed to promoting innovation in EV charging solutions, providing liquid-cooled cables that meet or exceed global standards such as GB/T, CCS1, CCS2, NACS and Megawatt ensuring compatibility with current and future EV models, and helping to build the next-generation EV infrastructure.