EV Charging Plugs

Megawatt Charging Cable 1500V 1500A for Heavy-Duty Commercial Vehicles

- Rated Power: 2250KW

- Rated voltage: 1500V DC

- Rated Current: 1500A

- IP protection class: IP 67

- Product description: Fiver's 1500V 1500A Megawatt Charging Cable delivers 2.25MW of power, cutting heavy-duty truck charging to minutes. Built for durability & safety with liquid-cooling. Boost fleet uptime and slash TCO.

1500V 1500A Megawatt Charging Cable: Powering Heavy-Duty Commercial Vehicle Electrification

As the core connection component for high-power charging of heavy-duty commercial vehicles (such as electric trucks, coaches, and construction vehicles) and megawatt charger, this 1500V DC 1500A megawatt charging cable is engineered to solve the critical pain points of "long charging time" and "insufficient high-power adaptability" in heavy-duty EV operations. It integrates liquid cooling technology, industrial-grade durability, and intelligent safety monitoring, providing a reliable, efficient, and stable energy supplement solution for heavy-duty commercial vehicles in logistics, public transportation, and engineering sectors—laying a solid foundation for the large-scale electrification of heavy-duty fleets.

Features of Fiver's 2.25MW Megawatt Charging Cable

1. Core Performance: Unleash Megawatt-Level Charging Potential

- Rated Specifications:1500V DC rated voltage and 1500A rated current, supporting megawatt-level charging power (up to 2.25MW when matched with compatible megawatt chargers), which can reduce the charging time of a heavy-duty truck with a 500kWh battery to within 30 minutes—greatly improving fleet operational efficiency.

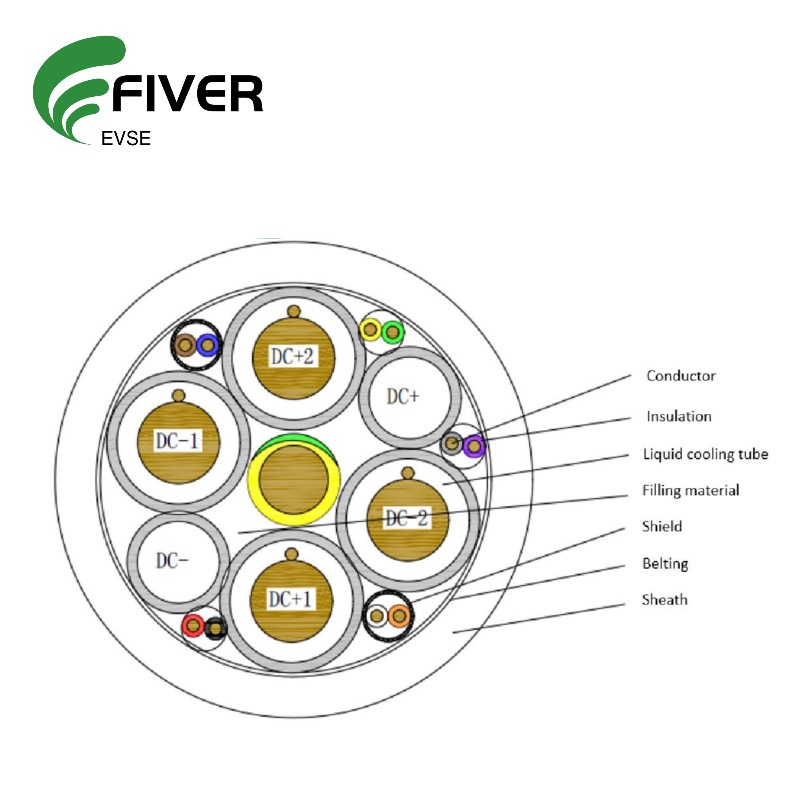

- Liquid Cooling Heat Dissipation System: Adopts an integrated liquid cooling design to address heat accumulation during high-power charging:

- Equipped with dual PT1000 platinum resistance temperature sensors (monitoring points T1-T4), real-time tracking the temperature of DC+/- terminals and cable cores, with a safety threshold set at ≤110℃ to prevent overheating.

- Compatible with industry mainstream coolants: (Shell E4 CCF, FUCHS TF8016/TF8025, SCC350EN) and matched with an 8kW dedicated cooling system, ensuring a coolant flow rate ≥8L/min and working pressure ≤7bar—effectively controlling temperature rise within 50K (per IEC standards).

- Coolant pipes: (inlet: φ8/φ10mm, return: φ8/φ10mm) support 360° rotation at the tail, adapting to diverse charging pile installation layouts and avoiding pipe torsion during heavy-duty vehicle docking.

2. Industrial-Grade Durability: Survive HDCV’s "Tough Environments"

- All-Weather Resilience:

- Extreme Temperature Resistance: Passes -35℃ low-temperature testing (120 hours, no brittle cracking) and 50℃ high-temperature testing (1000 hours, no insulation softening)—suitable for cold northern winters (e.g., Heilongjiang, China) and hot southern summers (e.g., Arizona, USA).

- IP67 Protection: IP67 grade protection inside the connector, IP44 when mated.

- Wear & Tear Resistance for High-Frequency Use:

- 10,000 Plug Cycles: 5 Years of Service Life: Calculated at 5 daily plugs (typical for HDCV fleets), it lasts 5+ years— The plug shell uses Sabic’s high-strength PA66+GF (glass fiber reinforced), withstanding 1.2m free falls (per IEC 60068-2-31) without cracking.

- Shock & Vibration Proof: Complies with ISO 16750-3 (HDCV electrical equipment vibration standards), enduring the shaking of heavy trucks during parking or charging—no loose terminals or wire detachment even after 1 million vibration cycles.

3. Heavy-Duty Safety: 3 Layers of Protection for High-Voltage Systems

- Double Insulation & High Voltage Withstand:

- Primary Insulation: Wires use cross-linked polyethylene (XLPE) insulation with an insulation resistance ≥500MΩ (1000V DC, 1 minute)—preventing leakage in humid environments.

- Secondary Reinforcement: The plug shell adds a 2mm thick silicone insulation layer, withstanding 4000V AC voltage (1 minute, no breakdown or flashover)—meeting the safety redundancy requirements of HDCV high-voltage systems (≥2x rated voltage).

- Reliable Grounding & Low Leakage:

- 25mm² yellow-green PE ground wire (twice the cross-section of ordinary cables), ensuring that ground fault current (up to 1000A) is safely discharged—avoiding electric shocks or fires.

- Leakage current ≤10mA(far below the HDCV safety limit of 50mA), compliant with EN 61851-23 (European HDCV charging standards) and GB/T 18487.1 (Chinese standards).

- Flame-Retardant Design: UL94-V0 flame retardancy (self-extinguishes within 10 seconds after removing the flame), preventing fire spread to the vehicle or charger in case of short circuits—critical for logistics parks with dense fleets.

4. User-Centric Design: Made for HDCV Operators

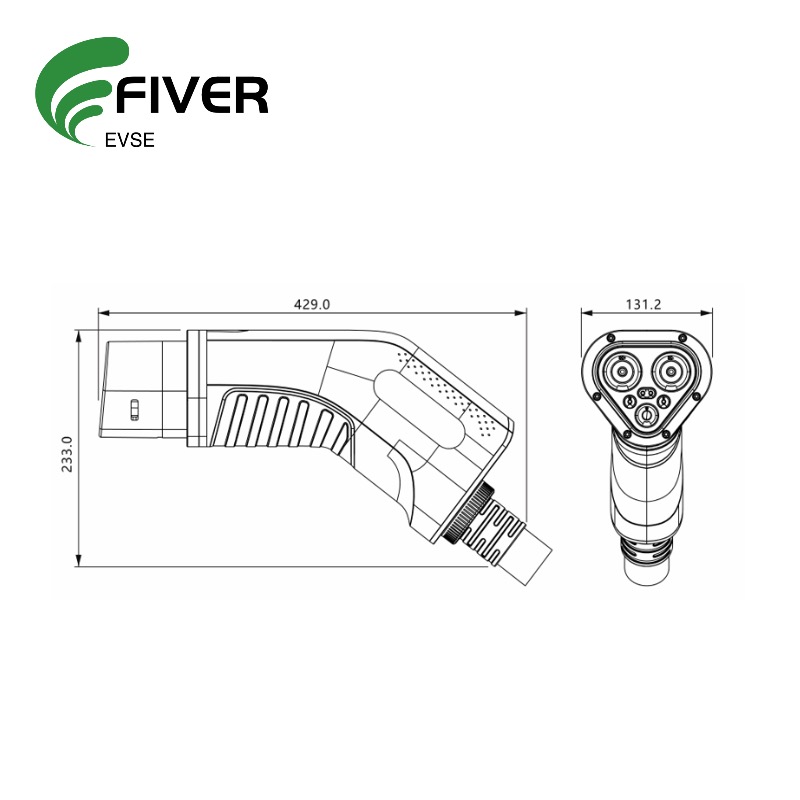

- Gloved-Hand Friendly Operation:The Megawatt charging connector handle features a non-slip rubber texture and an ergonomic curved design (133mm diameter), fitting comfortably in gloved hands (common for truck drivers/ground staff). Plugging force ≤100N (≈10.2kgf)—no need for excessive strength to connect/disconnect.

- Flexible Customization:Cable length: 0-5.5m (customizable, e.g., 4m for port cranes, 5.5m for semi-trailers with rear-mounted charging ports).Liquid pipe length: Up to 1.5m (optional), adapting to charging stations with built-in cooling systems.

- Easy Maintenance & Traceability:Laser-engraved nameplate (resistant to oil, corrosion, and fading) marks protection grade (IP54), product code (date + serial number), and rated parameters—enabling fleet managers to track maintenance cycles and batch information at a glance.

Parameters for Fiver's 2250KW MCS Charging Connector

| Standard | IEC62196-1:2022 IEC62196-3:2022 IECDTS 63379 IEC62893-4-1:2024 IECTS62893-4-2:2021 | |

| Rated voltage | 1500V DC | |

| Rated current | 1500A DC | |

| Voltage resistance | 4000V AC(Power) , 500v AC(Single) | |

| Insulation resistance | ≥500MΩ | |

| Degree of protection | Before insertion: IP54; After insertion: IP55 | |

| Electrical part: : IP67(Except the interface with socket) | ||

| Cycles life | ≥10000 | |

| lnsertion and withdrawal force | <100N | |

| Ambient temperature | -30℃ ~+ 50℃ | |

| Flame retardant rating | UL94V-0 | |

| Coating material of power contacts | Ag | |

| External cable diameter | Φ44±1.5mm | |

| Minimum bending radius | 10D | |

| Cooling circuit | Two inlet pipes and four outlet pipes | |

| Cooling medium | Shell E4 CCF(charging cooling fluid) | |

Applications for Fiver's Megawatt Charging Cables

1. Long-haul Freight High-speed Service Area Ultra-fast Charging Hubs.

2. Closed-scene Commercial Vehicle Centralized Depots

- A. Urban Bus & Sanitation Vehicle Hubs

- B. Port & Mine Special Vehicle Bases

3. Logistics Park Intensive Charging Terminals

4.Electric Maritime Vessels: Port & Inland Waterway Charging Hubs

5.Electric Aviation: Military & Civilian EVTOL Charging Stations.

6.Large-scale Energy Storage: Grid-connected "Source-Grid-Load-Storage" Systems.

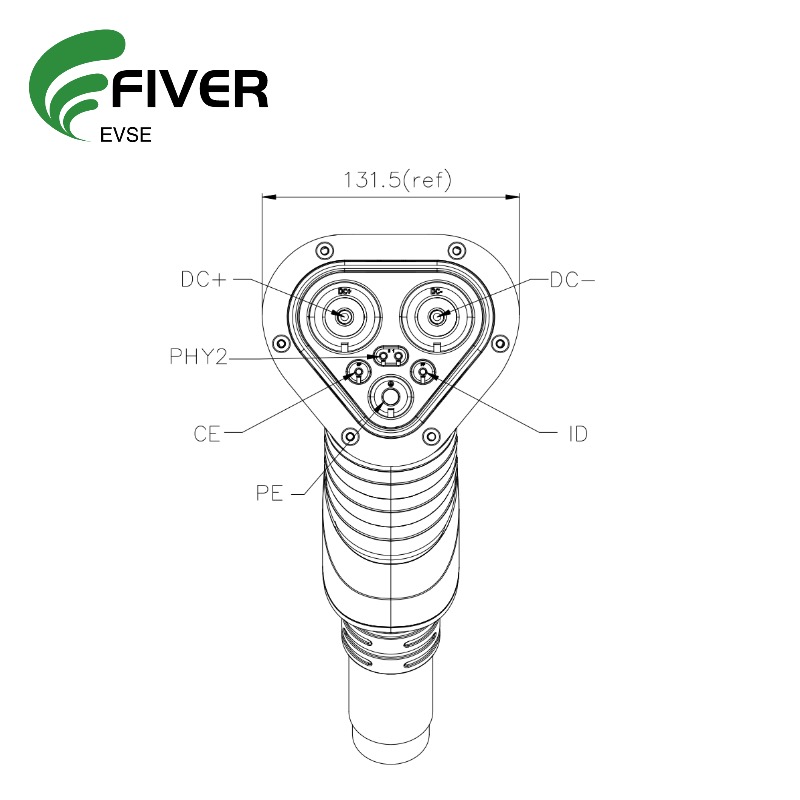

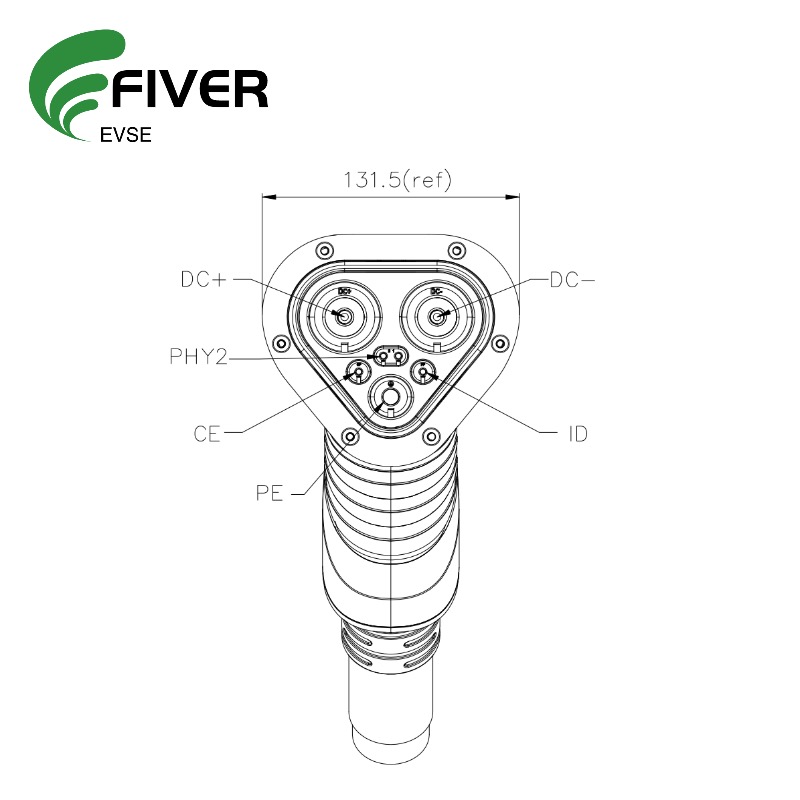

Pinout for the Megawatt Connector

Megawatt charging connector features a 7 pins layout. DC+/DC- ,serve as primary DC power contacts, tasked with transmitting high - voltage direct current (DC) electricity

PHY1+/PHY2- ; Acting as physical layer (PHY) communication contacts, they enable bidirectional communication between the charger and the EV; CE (Connection Confirmation) Contact,It is designed to detect the physical connection status between the charging gun and the vehicle’s inlet;

ID (Identification) Contact, This contact performs identification and parameter recognition functions; PE (Protective Earth) Contact, Serving as a protective earthing channel, it reliably connects the vehicle’s metal body and the enclosures of high - voltage components to the earth. In the event of leakage faults in the charging system, the PE contact can quickly conduct fault currents, ensuring the safety of personnel who come into contact with the vehicle.

Related Product: 1500V DC 1500A Megawatt Charging Port:

Categories

Latest News

Contact Us

Contact: Jerry Zhan

Phone: WhatsApp: +8618028699987

Tel: +86-023-20791348

Add: No.2201,AESC Center, Yubei District Chongqing China