Company news

Megawatt Charging (MCS): The Future of Heavy-Duty EV Charging & Fiver‘s Critical Components

As electric vehicles (EVs) expand beyond passenger cars into heavy-duty fleets—long-haul trucks, city buses, and off-highway machinery—a critical challenge emerges: traditional charging systems (like CCS) can’t keep up. A semi-truck’s 500kWh+ battery might take 8+ hours to charge with standard tech, grinding operations to a halt. Enter the Megawatt Charging System (MCS)—the global standard designed to deliver 1MW+ power, cutting charge times for HDVs to 30–60 minutes. At Fiver, we build the backbone of this revolution with our MCS Charge Inlet and 1500V 1500A Megawatt Charging Cable. Let’s break down what MCS is, how it works, and why it matters.

What Is Megawatt Charging (MCS)? History & Development

MCS isn’t just a "faster charger"—it’s a standardized solution built for the unique demands of HDVs. Let’s trace its evolution:

The Problem That Spawned MCS

By the early 2010s, passenger EVs relied on CCS (Combined Charging System) for fast charging (up to 350kW). But HDVs need far more: a Class 8 truck’s battery is 5–10x larger than a Tesla Model 3’s. CCS simply couldn’t deliver enough power to make HDV electrification practical—until the industry united.

The Rise of a Global Standard

In 2018, CharIN (Charging Interface Initiative)—a consortium of automakers, charger manufacturers, and utilities (including Tesla, Daimler, and ABB)—launched the MCS working group. The goal? Create a universal, safe, and high-power charging standard for HDVs. After 4+ years of testing (focused on durability, safety, and interoperability), CharIN finalized the MCS specification in 2022. By 2023, major OEMs (like Volvo Trucks, Freightliner) began integrating MCS into their electric models, and charging network operators (like Tesla Semi Superchargers) adopted the standard. Today, MCS is the de facto choice for HDV electrification worldwide—because it solves the "time-to-charge" problem that held back the industry.

The MCS Charging Interface: Cables, Inlets, Pinout & Communication Protocols

MCS’s power lies in its robust interface—designed to handle 1500V DC and up to 1500A (delivering 1.5MW+ of power). Two components are non-negotiable: the MCS charging cable (connects charger to vehicle) and MCS charge inlet (vehicle-side connection). But megawatt charging isn’t just about moving electricity—it requires a smart communication system to keep operations safe and efficient. Below’s a deep dive into Fiver’s engineered components and the protocols that make MCS work.

1. Fiver’s 1500V 1500A Megawatt Charging Cable

Our 1500V 1500A MCS Cable is built for the harshest HDV environments (depots, construction sites, highways). Key features:

- High-Power Handling: 1500V DC and 1500A current enable 2.25MW charging—enough to add 400kWh to a truck battery in 8 minutes (critical for minimizing fleet downtime).

- Durability: Reinforced TPU jacket resists oil, UV rays, and impact—essential for trucks operating in rain, snow, or dusty construction zones.

- Flexibility: Despite its power, the cable remains manageable for operators—even in extreme temperatures (-30°C to +50°C), a must for year-round use in cold climates or desert regions.

- Protocol-Ready Design: Integrated shielding for communication wires protects data signals (used in MCS protocols) from electromagnetic interference (EMI), ensuring reliable connectivity.

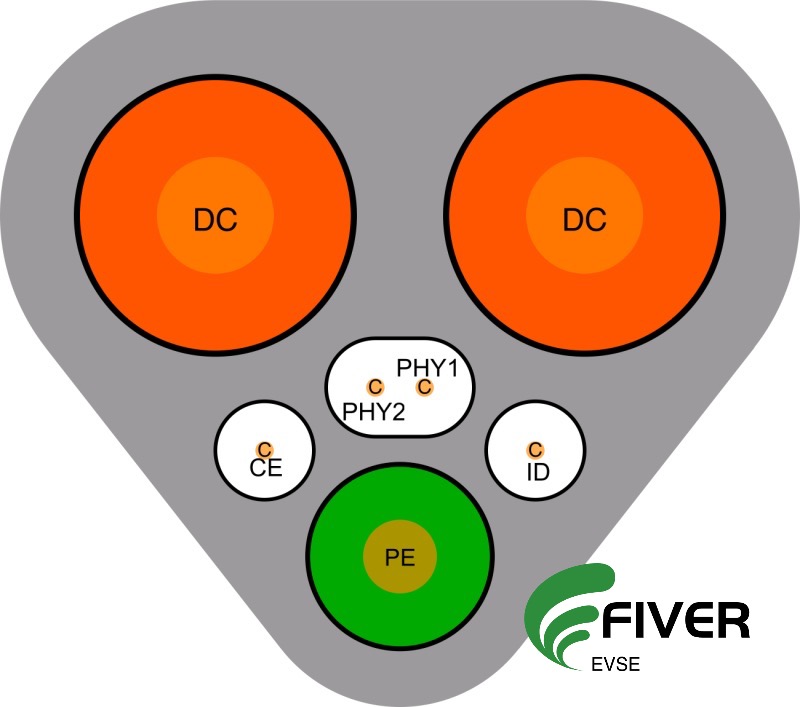

2. Fiver’s MCS Charge Inlet

The MCS Charge Inlet is the vehicle’s "entry point" for MCS power and data. It’s designed to withstand 10,000+ plug/unplug cycles (a requirement for fleet vehicles) and meets IP6K9K waterproof/dust-proof standards. Its precision-engineered terminals are optimized for both power and communication:

MCS inlet pin assignments:

Terminal Label

Function

Why It Matters (For Your Fleet)

DC+ / DC-

Primary DC Power Path

Carries ultra-high-voltage/current (up to 1500V DC, 1500A) directly to the vehicle’s traction battery. Fiver uses oversized, high-conductivity copper contacts to minimize heat buildup (a major risk at megawatt levels) and ensure stable power flow.

PHY1+ / PHY2-

Communication (Physical Layer)

Acts as the "data pipeline" for MCS protocols, transmitting real-time status and control signals. Our inlets feature shielded PHY contacts to resist EMI (common in industrial yards or near heavy machinery)—critical for reliable protocol performance.

CE (Connection Confirmation)

Physical Connection Verification

Acts as a "safety gate" before charging starts: it checks if the plug is securely latched, preventing arcing or overheating. Integrates with MCS protocols to block power until a valid connection is confirmed.

ID (Identification)

Parameter Matching

Works with MCS protocols to share vehicle/charger specs (e.g., battery type, max power), ensuring compatibility. Eliminates mismatches that could damage equipment or slow charging.

PE (Protective Earth)

Safety Ground

Diverts fault currents to protect operators and equipment. Protocols rely on PE status to validate system safety before initiating charging.

Every terminal in our MCS inlet is silver-plated to prevent corrosion (a common issue in humid/coastal areas) and tested to CharIN’s interoperability standards—so it works seamlessly with any MCS charger.

3. MCS Communication Protocols: The "Brain" Behind Safe, Smart Charging

MCS doesn’t just move electricity—it uses a layered protocol stack to enable intelligent, interoperable charging. These protocols turn brute-force megawatt power into a controlled process that’s safe, efficient, and future-ready. Here’s how they work, and why they matter for your fleet:

3.1 Physical Layer: Differential PLC (Power Line Communication)

The foundation of MCS communication is differential PLC, evolved from the HomePlug Green PHY standard (defined in ISO 15118-3). Unlike CCS’s "single-ended" PLC, differential PLC:

- Reduces EMI by ~40 dB: Critical for HDVs, where megawatt-level currents generate intense electrical noise (e.g., in mining or construction sites).

- Uses dedicated PHY1+/PHY2- terminals: Ensures data signals don’t interfere with power flow, keeping communication reliable even at 1500A.Fiver’s shielded PHY contacts in our inlet are engineered to maximize differential PLC performance—so your fleet’s charging sessions never drop out due to interference.

3.2 Application Layer: ISO 15118 (The "Command Center")

For real-world functionality (like Plug & Charge or V2G), MCS relies on the ISO 15118 standard—specifically the latest ISO 15118-20 revision. This protocol enables:

- Plug & Charge: Automatic authentication and billing (no cards or apps needed). For fleets, this cuts driver wait time and simplifies expense tracking.

- Dynamic Power Adjustment: Real-time tweaks to charging speed based on battery data (e.g., temperature, SOC). Prevents battery damage and optimizes charge time.

- V2G Readiness: Bidirectional energy flow (vehicle-to-grid) for future grid services. Your fleet could sell excess battery power back to utilities during peak demand—creating a new revenue stream. Fiver’s MCS components are pre-certified for ISO 15118, so you won’t need to upgrade to support these features later.

3.3 System Coordination: SAE J3271

To ensure MCS works across all HDVs, chargers, and grids, SAE J3271 (especially J3271/2) orchestrates protocol harmony. It unifies:

- SAE J2931: Messaging between vehicles and chargers (e.g., "start charging" commands).

- SAE J2847: Communication within charging infrastructure (e.g., between a charger and its energy meter).

- SAE J1939: Integration with HDV onboard networks (CAN bus), so the vehicle’s internal systems (e.g., battery management) sync with the charger.This means a Fiver-equipped Volvo truck can charge at a Tesla Semi Supercharger or a ChargePoint MCS station—no compatibility headaches.

3.4 Auxiliary Protocols: For Real-World Integration

MCS adds auxiliary protocols to handle practical fleet needs:

- Ethernet: Secures "Plug & Charge" authentication (via encryption) and sends high-bandwidth data to cloud platforms (e.g., charging logs for fleet managers).

- RS-485: Connects to legacy equipment (e.g., older energy meters) or enables long-distance communication in large depots.Fiver’s cables include dedicated wires for these protocols, ensuring your MCS setup integrates with existing fleet infrastructure.

Applications of MCS Charging: Where It Makes the Biggest Impact

MCS isn’t just for trucks—it’s transforming any HDV that needs fast, reliable charging. Here are the key use cases where Fiver’s MCS components (and their protocol compatibility) shine:

1. Long-Haul Electric Trucks

Semi-trucks (like the Tesla Semi or Volvo FH Electric) travel 500+ miles per day. With MCS, drivers charge during 30-minute rest breaks—made seamless by ISO 15118’s Plug & Charge. Our 1500A cable handles the power, while protocol-compatible inlets ensure interoperability with highway charging networks.

2. City Buses & Coaches

Public transit agencies need quick "opportunity charging" between routes. MCS charges buses in 15 minutes, and SAE J3271 ensures compatibility with depot chargers. Fiver’s compact inlet fits bus chassis, and flexible cables make daily use easy for staff.

3. Off-Highway Vehicles

Mining trucks and construction equipment operate in EMI-heavy environments. Fiver’s shielded PHY contacts and differential PLC support keep charging reliable, even near heavy machinery. MCS cuts downtime from 8 hours (CCS) to 45 minutes—saving $10,000+/hour in lost productivity.

4. Marine & Rail (Emerging Use Cases)

Ferries and commuter trains need saltwater-resistant components and reliable communication. Fiver’s anti-corrosion inlets and protocol-ready design let ferries charge in 30-minute port stops (1MW = 2 hours of range) and trains top up during layovers.

The Future of MCS Charging: What’s Next?

MCS is still in its early days—but the future is bright. Here’s how the standard (and Fivers products) will evolve, built on its robust protocol foundation:

1. Higher Power: Beyond 2.25MW

By 2027, CharIN plans to update MCS to 2MW+ charging. Fiver is engineering cables/inlets to handle 2000A—with protocols (like ISO 15118-20) already ready to manage higher power safely.

2. V2G for Fleet Revenue

MCS’s ISO 15118 protocol will enable widespread V2G. Imagine your electric bus fleet discharging energy to the grid during heatwaves—earning revenue while supporting grid stability. Fiver’s inlets are prepped for bidirectional communication.

3. Global Interoperability

CharIN is expanding MCS to Asia and South America, with SAE J3271 ensuring global compatibility. Fiver’s UL/IEC/GB-certified products work anywhere—perfect for multinational fleets.

4. Medium-Duty MCS

Fiver is developing a compact MCS inlet for delivery vans/garbage trucks. It retains 1.5MW power and full protocol support but fits smaller chassis—bringing MCS benefits to more fleets.

Why Fiver Is Your MCS Partner

MCS works only if components and protocols are reliable. At Fiver, we don’t just sell cables and inlets—we engineer MCS solutions that:

- Meet Global Standards: CharIN-certified, with ISO 15118 and SAE J3271 compliance built in.

- Solve Fleet Pain Points: Shielded contacts for EMI resistance, corrosion protection for harsh environments, and customization (e.g., 10m cables for mining).

- Future-Proof Your Investment: Ready for 2MW charging and V2G, so you won’t need to replace components in 3 years.

Ready to build a faster, smarter charging system for your HDVs? Explore our MCS Charge Inlet and 1500V 1500A MCS Cable, or contact our team to learn how we’ll tailor MCS to your fleet.

Categories

Latest News

Contact Us

Contact: Jerry Zhan

Phone: WhatsApp: +8618028699987

Tel: +86-023-20791348

Add: No.2201,AESC Center, Yubei District Chongqing China