CCS2 Connector & Charging Cable

1000V 250A CCS2 Connector 250KW CCS2 Charging Cable for DC Fast Charging

- Rated Power: 250KW

- Rated voltage: 1000V DC

- Rated Current: 250A

- IP Protection Class: IP 67 ( working condition)

- Product description: Our 250A CCS2 Charging Connector adopts the ultrasonic terminal welding technology, this technology ensures minimal contact resistance, resulting in a safer and more reliable charging process. Additio

1000V 250A CCS2 Connector Neutral Cooling 250KW CCS2 Charging Cable for DC Fast Charging

250A CCS2 Connector Specifications:

| Rated Current | 250A |

| Rated Voltage | 1000V DC |

| Insulation Resistance | >500MΩ |

| Contact Resistance | 0.5 mΩ Max |

| Withstand Voltage | 3500V |

| Flammability Rating | UL94V-0 |

| Mechanical Lifespan | >10000 Mating Cycles |

| Casing Protection Rating | IP67 |

| Casing Material | Temperature |

| Terminal Material | Copper alloy, silver plated |

| Terminal Temperature Rise | <50K |

| Insertion & Withdrawal Force | <100N |

| Certification | TUV / CE / CB / UKCA |

| Warranty | 24 months/10000 Mating Cycles |

| Operating Environment Temperature | -30℃- +50℃ |

Product Features for 250KW CCS2 Charging Cables:

1. Ultrasonic Terminal Welding Technology.

Our 250A CCS2 Charging Connector adopts the ultrasonic terminal welding technology. Unlike traditional crimping methods, this technology ensures minimal contact resistance, resulting in a safer and more reliable charging process. Additionally, it significantly reduces the temperature rise during use, leading to a longer service life for the product. With the pins of the EV plugs securely welded, you can enjoy a seamless charging experience every time.

2. Quality Assurance.

This 250A CCS2 Connector is designed to comply with the standard of IEC62196, ensuring compatibility with a wide range of electric vehicles. With a maximum voltage of 1,000 volts DC, it provides a powerful and efficient charging experience. The connector also boasts a multitude of safety features, further enhancing its reliability. It is built to withstand more than 10,000 times of plugging and unplugging, making it a durable and long-lasting solution.

3. Durable and Reliable. IP67 Level Protection

To enhance durability and reliability, the terminal and cable crimping parts of the CCS2 connector are carefully wrapped with high-quality rubber. This not only provides added protection but also allows the connector to achieve an impressive waterproof level of IP67. So, whether you're charging your EV in rain or shine, you can be confident that the connector will remain perfectly functional and safe.

4. Certifications:

When it comes to certifications, we have obtained TUV, CB, CE, and UKCA certificates. These certifications are a testament to the quality and safety standards that we uphold. With our CCS2 connector, you can charge your electric vehicle with peace of mind, knowing that it meets international standards and regulations.

5. OEM & ODM Service welcomed

As an EV Charging Cable manufacturer we understand the importance of customization, which is why our CCS2 connector not only supports simple logo customization but also offers the option to customize the entire function and appearance. This allows you to tailor the connector to your specific needs and branding requirements. Whether you're an EV charging station operator or a manufacturer looking to enhance your product offerings, our CCS2 connector is ready to meet your unique requirements.

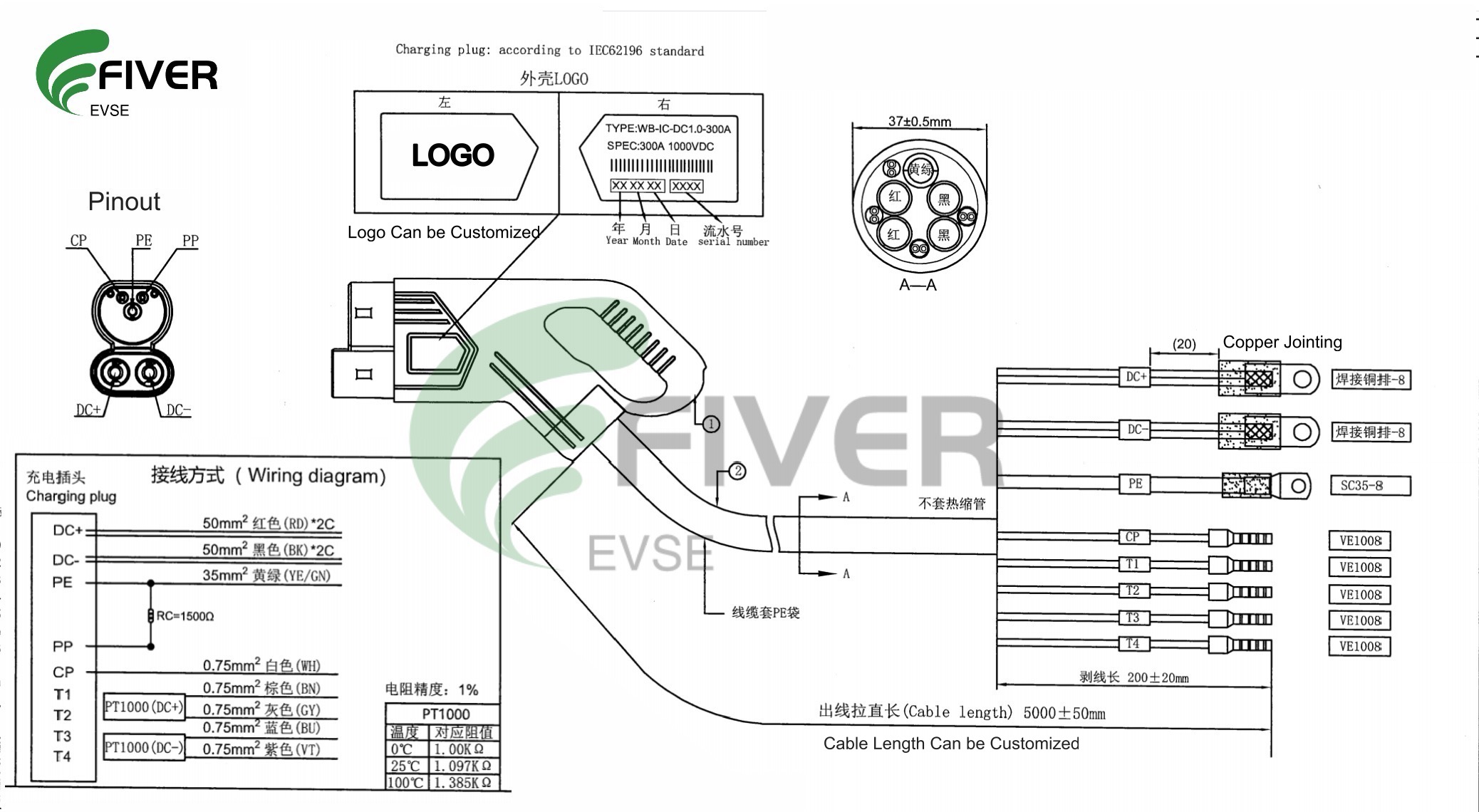

The Drawing for 1000V DC 250A CCS2 Charging Cable for High Power Charging

Tags:

#EV Charging Cable, #250A CCS2 Charging Plug, #250A CCS2 Charging Cable, #250A CCS2 Connector #DC Fast Charging

#High power charging #250A CCS2 Charging Cable Neutral Cooling

Categories

Latest News

Contact Us

Contact: Jerry Zhan

Phone: WhatsApp: +8618028699987

Tel: +86-023-20791348

Add: No.2201,AESC Center, Yubei District Chongqing China